Quality control

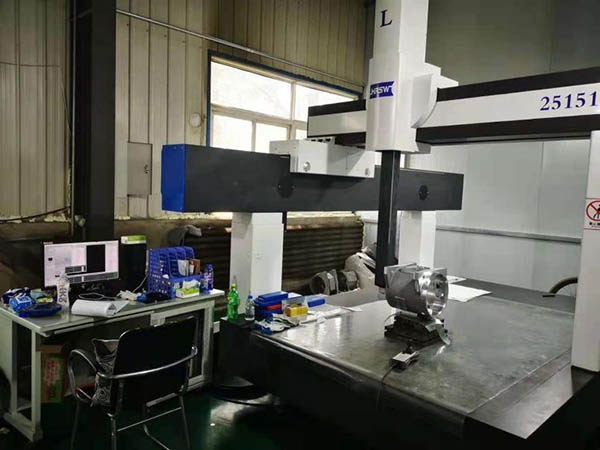

Hicent provide high-quality parts by excellent process control techniques and advanced equipment. Our quality management start from material identification, quality inspection to final products testing. We have strict standard for raw material selecting, we do first article, in-process inspection and final inspection to ensure the quality .Which means we monitor every project step for quality assurance.We have full advane ispection measuring and testing equipment such as CMM , Laser precision detection, internal dial gauge,micrometer,thread gages,plain plug gauge, calipers, block gauge, roughness detection sample block,roughness tester etc. to satisfy our customers’ exact specification requirements. We would finish 100% inspection and we could provide full inspection reports as customer requests before shipment.

We also implement Visual Quality Standard for surface finish service All our production will be inspected by a consistent method with same standard, so we can guarantee that any parts form Hicent will beyond your expectation.

Hicent’s machined parts are used in millions of devices and machines worldwide. Some components are used in high precesion tech applications including military field. As a professional precision machining manufacturer, we know nothing is more important than production quality. You can always rely in Hicent’s quality

Hicent is also focus the customers feeling. We are always at the first time to help in doing the whole aftersales service. Sincerely wish long-term cooperation.

CATEGORIES

- Products applicated in Medical Device Industry

- Products applicated in UAV Industry

- Products applicated in Aviation Industry

- Products applicated in Automotive Industry

- Products applicated in Communication Electronics

- Products applicated in Mold Components Processed and Fixture

- Products applicated in oil,gas and other heavy equipments

CONTACT US

Name: Crystal Gao

Mobile:+86 15140066537

Tel:

Whatsapp:8615140066537

Email:crystal@hicentcncmachining.com

Add:No.83-31, Puhe Road, New Shenbei District, Shenyang, Liaoning, China